|

Water Treatment Plant Progresses, March 2009 operation on schedule

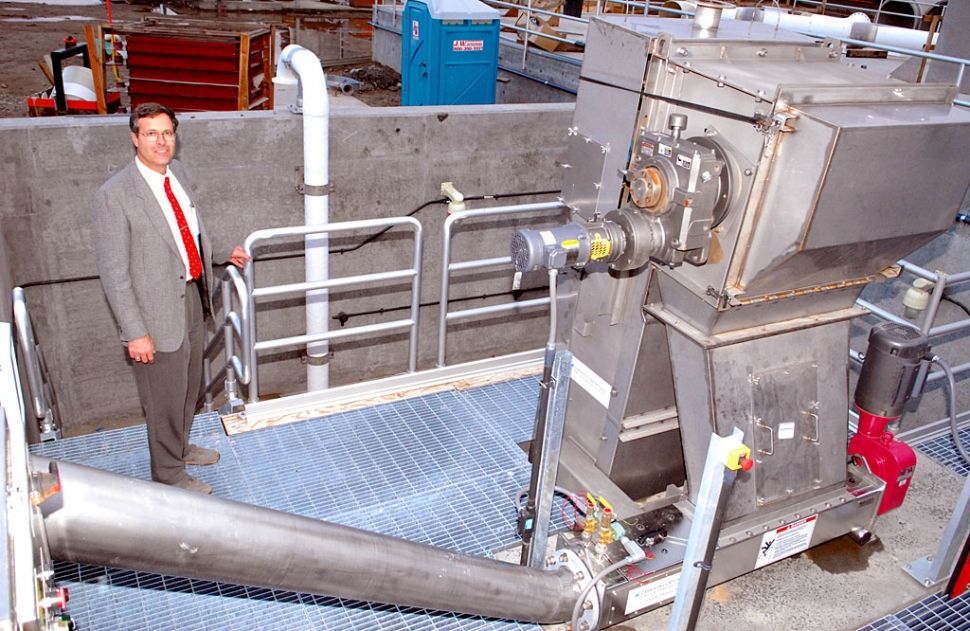

Bert Rapp, Fillmore’s Director of Public Works, has reason to be proud of the new water treatment plant. It is coming in ahead of schedule and more than $3 million under budget. The plant is about 85 percent completed. And will be running in March. By Mariandrea Mueller — Thursday, January 1st, 2009

“Construction is coming along smoothly,” said Public Works Director Bert Rapp of Fillmore’s 80% completed Water Treatment Plant. The Gazette staff got a sneak peek at how it all works last week, and the plant will be open for public tours in March 2009. Rapp pointed out that the most complicated part of the construction is starting up the plant. The plant must be working properly by September 9, 2009. In March, the plant will process clean water for a two or three week basic test of the system. In April or May, the plant will begin operating. The wastewater enters the plant through underground pipes and is split into two channels. The wastewater goes through a coarse screen which removes larger pieces of junk. The junk goes into dumpsters. All of the dumpsters are expected to be emptied weekly. The plant is designed to take advantage of the electric company's varying rates. The plant must run constantly to maintain operational bacteria levels, but equalization basin storage will allow the plant to store some wastewater to be processed when the electric company's rates are lowest. After going through a coarse screen, the water is either stored or continues the process. The concrete basin in which the water is stored is coated with a yellow protective material that will protect the concrete for 20 to 30 years. The hydrogen sulfide gas is kept out of the water to minimize corrosion. Every portion of the processing plant which has the potential to stink will not release odors because the air will be suctioned away by blowers to a biofilter containing wood chips which will remove the sulfides and any other odor-producing materials from the air. The blower room is noisy, so it vents out noise toward the highway. There are three beds of deodorizing wood chips. The wastewater then goes to a grit classifier, which is a seven or eight foot deep cone. Gravity and the shape of the cone cause the water to spin. Sand and other grit collects in the bottom and is pumped into a dumpster. The wastewater passes through fine screens. The screens are self-cleaning and can capture materials even as small as hair. After passing through fine screens, the water enters the headworks for the oxidation ditches, which remove nutrients. The oxidation ditches include three different types of bacteria in different sections: anaerobic (without oxygen), hybrid, and aerobic. Air-flow pipes in the bottom of the aerobic section ensure that the bacteria have plenty of oxygen. The wastewater passes through membranes to a screw-press for dewatering. The biosolids are converted into pellets off-site by Toland. The treated water goes into a water holding tank, and is distributed for public irrigation of schools and parks, or percolated back into the ground. Unlike the current water treatment plant, this plant will not discharge any water into the river. Not having river discharge avoids costly complications. Besides plant buildings, the site contains a maintenance building, and an office building with a lab. |